Pinball Golf

Pinball Golf

At a previous job, the company bid on designing and building interactive mini-golf courses. This was a project outside of our usual scope. To familiarize ourselves with the task and demonstrate our capabilities to the client, it was decided to develop a prototype based on one of the requested designs. This approach allowed us to learn what we were getting into while showcasing our skills.

I was responsible for electronics integration, managing a team of two programmers with limited hardware experience. We were given four weeks to complete the prototype, all while maintaining our existing project commitments.

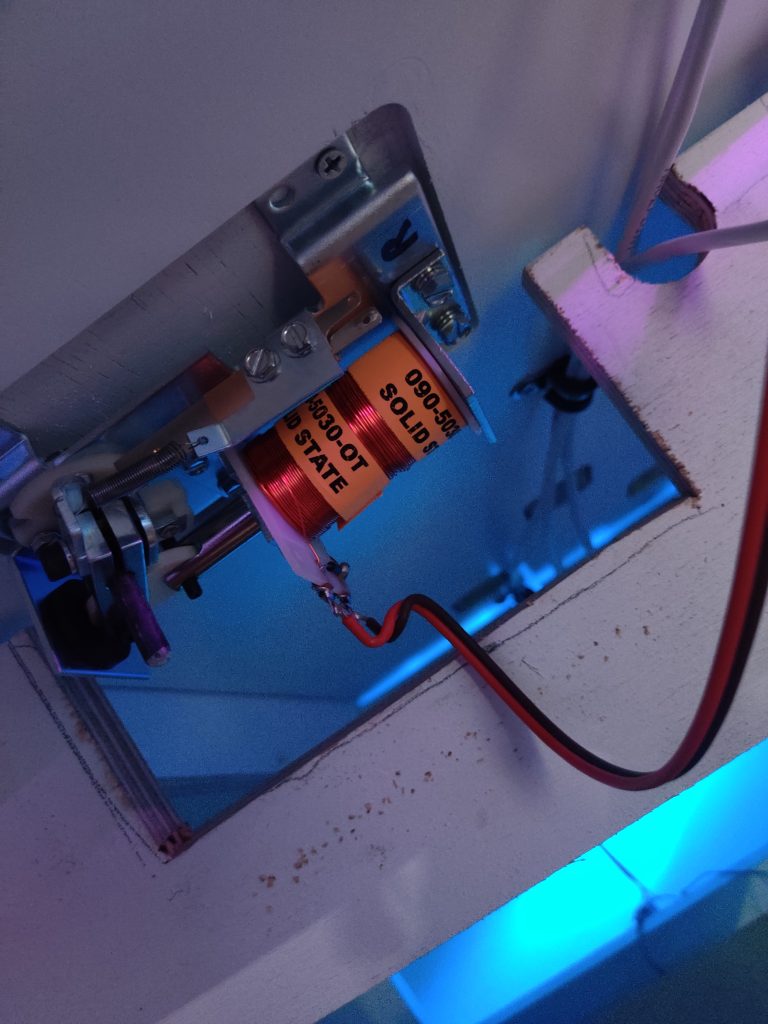

My primary focus was the electromechanical functions, and since the prototype was designed as a scaled-up pinball table, I had no prior experience working with pinball machines. I quickly immersed myself in learning everything I could about their inner workings. I also sourced parts from distributors and ordered a set of components for a full table to begin testing. By the end of the first week, as the parts began arriving, I was confident we had enough knowledge to proceed with the prototype.

Initial math process

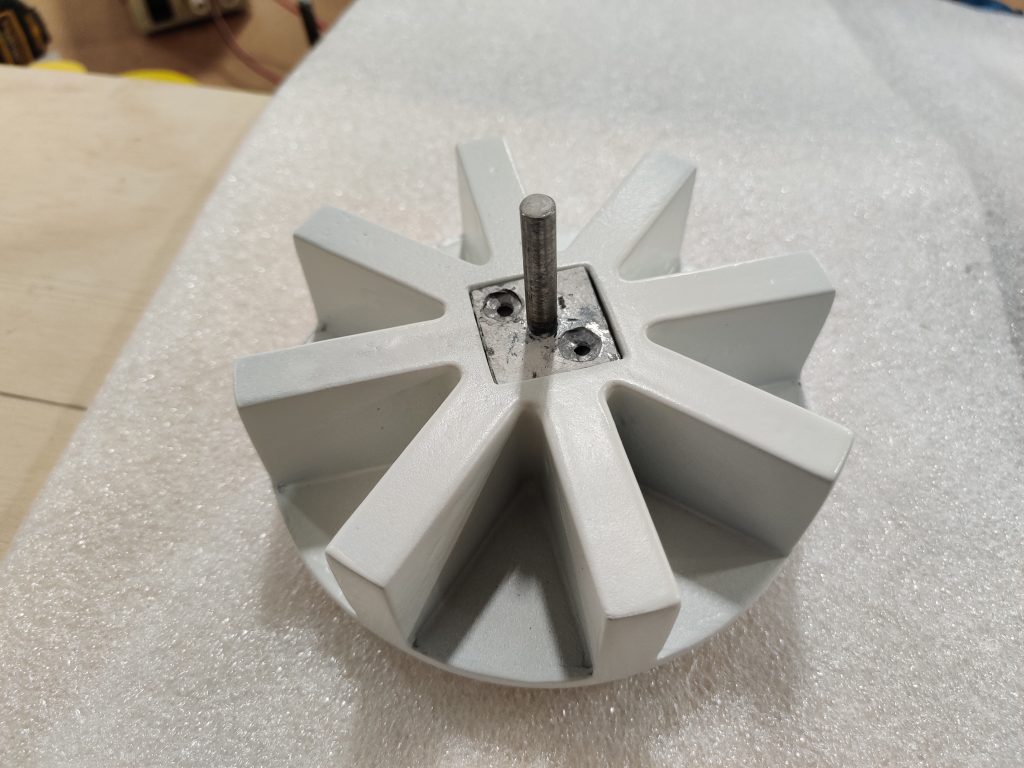

As we began working, we realized that scaling up the tabletop components to match the size of a golf ball introduced new challenges. While the strength of the coils suggested the functionality would not be compromised, we were unsure how the material of the golf ball and our castings would interact. To explore this, we built several test jigs to experiment with the flippers, spinners, and slingshots. We found the flippers to be more than adequate, and the slingshot geometry had minimal impact, allowing us to prioritize aesthetics in the final design.

The score was displayed on a TV screen, with the prototype tracking scores for two golf holes. The center hole was worth three points, and the lower hole was worth one. We used two break-beam sensors wired to GPIO inputs on a Raspberry Pi to track the score. As the ball fell into the center hole, it passed both sensors. To avoid debounce issues in the code, we opted to allow both sensors to count the score, with the center sensor contributing two points, making the total score for the center hole three points. This solution, which I still find amusing years later, worked well. The score display code was reused from a previous project and was written in Python using Tkinter. The lighting was controlled by a single ESP32 microcontroller.

Durring this project, there was no dedicated person coordinating between the design, build, and electronics teams. The design team was introduced to the electromechanical components, but there was no one closely collaborating with them to ensure the components were fully understood. As seen in the accompanying photos, these kinds of miscommunications can lead to mistakes, especially when projects are rushed. For example, the solenoids running the flippers were mirrored designs for the left and right, and they needed to be oriented correctly to ensure the weight of the flipper would return it to the de-energized state automatically.

These issues made me realize the need for better coordination between departments, which ultimately led me to take on the role of facilitating collaboration across teams.

Prototyping is often an interesting process, especially in situations like this, where the goal is not only to create a functional product but also to present a minimum viable product, a glimpse of what’s possible.

There are several improvements that could enhance the durability and functionality that were not requirements of this prototype:

- The playfield, which was painted solid blue, would benefit from a durable printed laminate to prevent wear and allow for more detailed graphics and theming.

- The interactive elements on the play surface were cast, but milling them from HDPE or similar material would provide better durability and aesthetics.

- Mounting brackets could be designed to replace the crude wooden blocks I used to hold the spinner motors.

- We reused a lot of electrical components we had in stock, but a more efficient and cleaner wiring design could be achieved by sourcing components better suited for this type of machine.

- The ball sensors were IR break-beams, as we had stock available, but using a micro switch with a long actuator (similar to a coin door switch or rollover switch) would be more cost-effective and reliable for the environment.

- The playfield should be covered to prevent people from touching the moving parts.

- Overall, durability could be significantly improved with better material choices and design.

- The foot pedals chosen by the client for the test were small and difficult to use. A button pedestal or larger pedals would be ideal.

Despite the challenges, I found working with the electromechanical pinball components more enjoyable than I anticipated. I plan to incorporate some of these components into future art pieces I design. Given the constraints of this project, we were unable to use active bumpers, but I would love the opportunity to work with them in the future.